Supplier Management

Suppliers of Shin Kong Security are primarily group businesses, such as Shinsoft Co., Ltd., which provides digital surveillance, access control products, smart logistics, and information platform services; Shincluster Electronics Co., Ltd., which primarily provides security control products (video intercom system, perimeter sensor, parking management system, access control and attendance system, monitoring management system, and various security equipment supply). Furthermore, according to the different business attributes of the business groups, the executives of each division at SKS are responsible for supervising the group's operations. In doing so, they not only improve communication efficiency, but also allow the concept and practice of corporate social responsibility to be implemented in the business group's operations, to create a sustainable supply chain.

Supplier Management Model

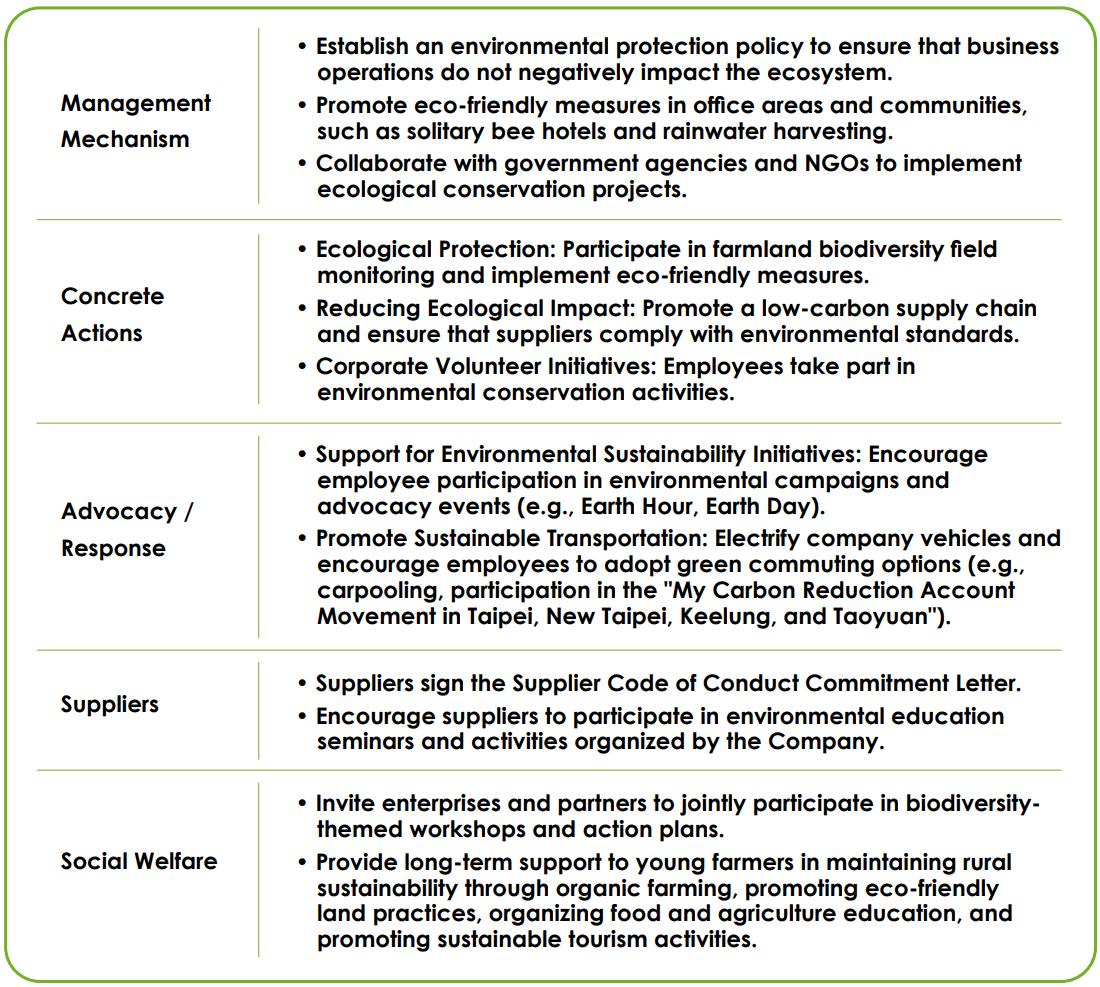

The Company regards suppliers as a key component of its sustainability efforts and requires them to strictly adhere to the Supplier Code of Conduct Commitment Letter, which aims to achieve a balance among economic, social, and environmental interests, as well as sustainable environmental development. To this end, the Company has established a supplier support program that integrates selection, auditing and guidance, performance evaluation, and training. Based on cooperation, sustainability requirements are incorporated into the daily management of the supply chain. Additionally, the Company holds weekly domestic and international equipment procurement meetings to collaborate with warehouses and relevant business units in identifying and managing risks such as insufficient supplier capacity, quality issues, or supply chain disruptions. In 2024, 100% of new suppliers signed the Supplier Code of Conduct Commitment Letter; existing suppliers are also required to comply with the guidelines upon contract renewal. Each year, the Company checks the official violation inquiry system for labor-related offenses to verify whether any suppliers have been penalized for violating local minimum wage standards. If any such violations are found, the suppliers are required to provide an explanation and implement corrective measures.

- Suppliers must strictly comply with and sign the Supplier Code of Conduct Commitment Letter.

- Construction and related operations contractors must obtain occupational safety and health management licenses.

- Local suppliers must obtain a valid registration certificate issued by the local government in accordance with their business type.

- A supplier audit task force has been established to conduct audits in accordance with the Supplier Code of Conduct Commitment Letter, along with tracking and follow-up on corrective actions for deficiencies, with the aim of jointly improving supplier quality.

- Irregular training sessions are held to effectively improve occupational safety and health performance through various forms of guidance and communication. The courses cover occupational safety and health, as well as regulatory risks.

Number & Percentage of Suppliers Signing the Commitment

Supplier Categories

Supplier Evaluations

In 2022, the Company established a supplier quality system and process capability evaluation standard, categorizing key suppliers into four levels: A, B, C, and D. Suppliers that pass the supplier management evaluation are eligible for contract renewal at the end of the year; those who fail are either designated for improvement guidance or disqualified from renewing their contracts. Penalties for certain suppliers are imposed in accordance with the Supplier Evaluation and Reward and Penalty Guidelines. Our management goal is to increase the proportion of sustainable suppliers. New suppliers are screened using the Regular Supplier Evaluation Form, in which environmental standards are one of the evaluation criteria. We invite suppliers to join us in making positive contributions to society, the economy, and the environment while minimizing negative impacts and jointly advancing toward a sustainable supply chain. Since 2021, on-site inspections have been suspended due to the COVID-19 pandemic, prompting the Company to accelerate its digital transformation. For example, some in-person vendor meetings have been replaced with telephone bidding, which reduces the need for cross-regional movement of personnel and clients while also creating new service models. In 2024, the Company conducted on-site audits for two key suppliers. Moving forward, the number of on-site evaluations will be increased. The Company will regularly assess supplier performance to ensure continued compliance with sustainability standards and will organize relevant training sessions as needed to enhance supplier management and support, thereby ensuring supply chain stability and sustainability.

Sustainable Environmental Education Practices